时间:2023-04-10

时间:2023-04-10 阅读:

873次

阅读:

873次

Process Description.

A trip down the pipe column to meet the top casing cementing and bare-hole segmentation fracturing construction needs.

The ball holder can be used to drill the fracturing sleeve, so that the construction can be completed at the same time.

The upper part of the cementing sleeve is equipped with a sealing mechanism to ensure the wellbore integrity of the fractured tubular column during fracture pumping.

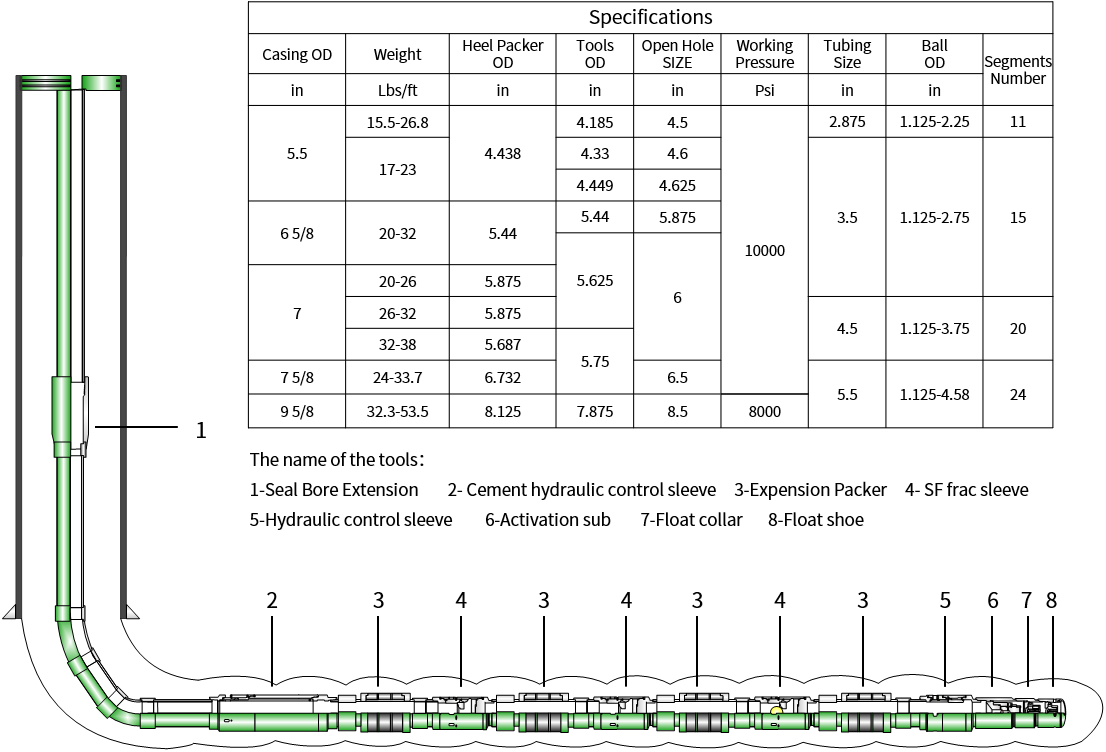

Tubular column structure.

Casing + return joint seal cylinder + cementing hydraulic sleeve + naked eye packer + ball drop fracture sleeve + naked eye packer + differential pressure sleeve + pressure bearing short joint + floating shoe.

Insertion of seal barrel + back joint seal insert.

The 3.5" tail pipe segmented fracturing column slip set can be divided into 15 segments with ball drop sizes of 1.125"-2.625".

The 4.5" tailpipe fracturing column slip set is available in 20 sections with a ball size of 1.125"-3.75".

The 5.5" tail pipe fracturing column slip set is available in 24 sections with ball sizes 1.125" - 4.58".

Contact Us

(0571)85066306

中文